Truss Day: A Key Milestone in Your Home Construction Journey

Truss day marks a significant step in building your new home. It’s an exciting moment when the roof trusses are delivered, lifted into place using heavy equipment, and installed within hours. Once braced and ready for roof sheathing, the framework for a watertight structure is complete. The next steps—plywood, shingles, and a fully waterproof roof—aren’t far behind.

But have you ever wondered why modern homes use trusses, while older homes rely on rafters? Understanding the evolution of roof framing sheds light on why trusses are the go-to choice for today’s construction projects.

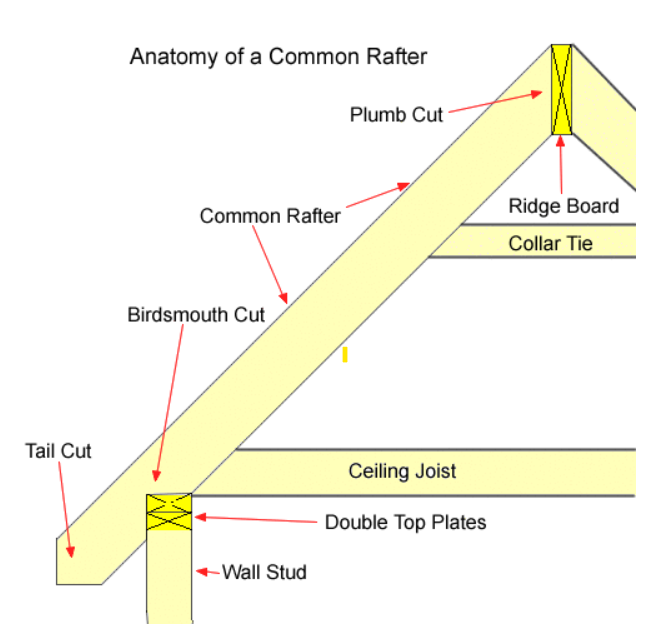

Rafters: The Traditional Roof Framing Method

If you live in an old home and peek in the attic, you’ll likely see stick-framed rafters. These were manually cut and assembled on-site by skilled carpenters using framing lumber. The roof sheathing often consisted of dressed tongue-and-groove boards or rough-cut lumber, with ceiling joists added to create a flat ceiling.

While many old carpenters framed roofs in ways that no longer meet modern building codes, their craftsmanship speaks volumes. The fact that these houses are still standing demonstrates the strength of traditional techniques. For example, in my own home, the rafters lacked a ridge board or beam; instead, a simple piece of 1x4 lumber held the plumb-cut rafters together. While the roof isn’t as straight as it once was, I’m confident it will last another 70 years.

However, rafters have limitations. The span is restricted by the size of the lumber used for both rafters and ceiling joists. In many older homes, central walls or beams were necessary to support the roof, particularly in long, narrow bungalows common in Renfrew County. Additionally, rafter installation requires significant on-site labor and expertise, which can drive up costs.

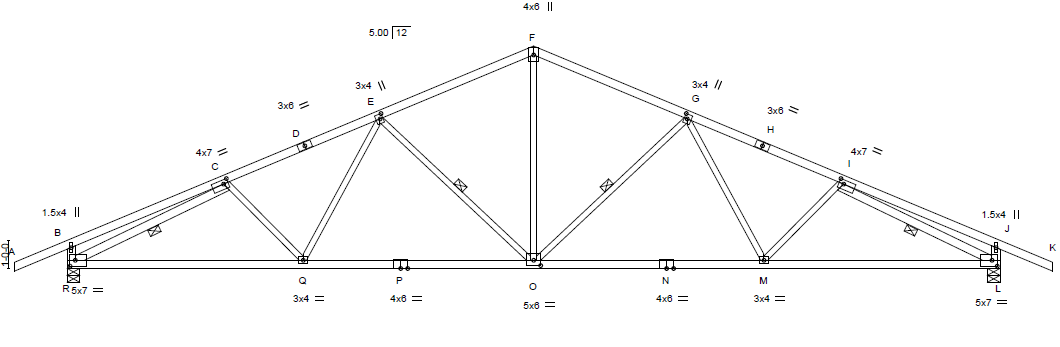

Trusses: A Modern Roofing Revolution

The introduction of roof trusses revolutionized home construction. Offering longer clear spans without the need for central walls or beams, trusses make it possible to build larger, more open homes.

Early trusses were built on-site using plywood gussets to connect the webs and chords. While effective, this method was labor-intensive. The game-changer came in the 1950s with the invention of the metal connector plate. This innovation allowed trusses to be factory-manufactured with precision. Lumber was laid out on large tables, metal plates were pressed into place, and completed trusses were shipped to the jobsite ready for installation.

This advancement reduced labor costs, sped up construction timelines, and enabled more architecturally exciting roof designs. Today, trusses are engineered to meet regional snow load and building code requirements, ensuring durability and safety.

Rafters vs. Trusses: When to Choose Each

While trusses offer numerous advantages, there are still scenarios where stick-framed rafters are the better choice:

- Small Additions or Outbuildings: For short spans, rafters are quick and cost-effective.

- Difficult Access: Lumber is easier to transport to tight or remote sites compared to large, pre-fabricated trusses.

- Exposed Framing: Rafters are ideal for porches or rooms with visible beams. Pairing rafters with decorative sheathing, such as V-joint pine, can create stunning curb appeal.

For new home construction, however, trusses are the preferred choice. They eliminate design limitations, simplify site logistics, and speed up the building process.

Building a Stronger Roof

When it comes to roof sheathing, the Ontario Building Code specifies a minimum thickness of 7/16-inch OSB. At Quality Homes & Renovations, we go above and beyond by using ½-inch SPF plywood. This material is stronger and less prone to sagging between trusses, ensuring a durable, long-lasting roof.

Whether you choose trusses or rafters, making informed decisions about your roofing system is critical to the success of your project. With the right materials and construction methods, your home’s roof will stand the test of time.